Applications: Aerospace Industry

- Scratches and Dents: Learn More

- Pitting and Corrosion: Learn More

Critical components in aircraft and space vehicles can be damaged by foreign objects during repair processes or by unexpected wear during normal operation. Any material removed from a surface by a scratch or a gouge or any deformity of a surface, such as a dent, may compromise the safety of the vehicle.

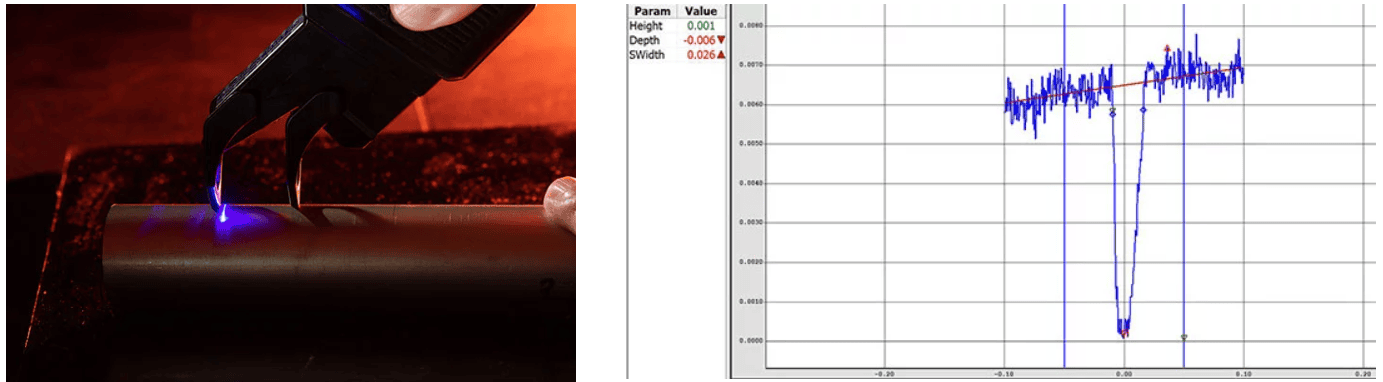

Scratches and gouges on tubes, pipes and other surfaces must be measured to determine how much material has been removed, and thus, how much of the original surface or wall is remaining. Depth micrometers and other mechanical devices cannot provide meaningful measurements because of the contour of the surfaces and the small features that have to be measured. The depth and width of any visible wear or gouge must be measured to determine if the part is still qualified for flight. Thresholds for the amount of material that can be missing are in the thousandths of an inch, so the measurement instrument must achieve this resolution

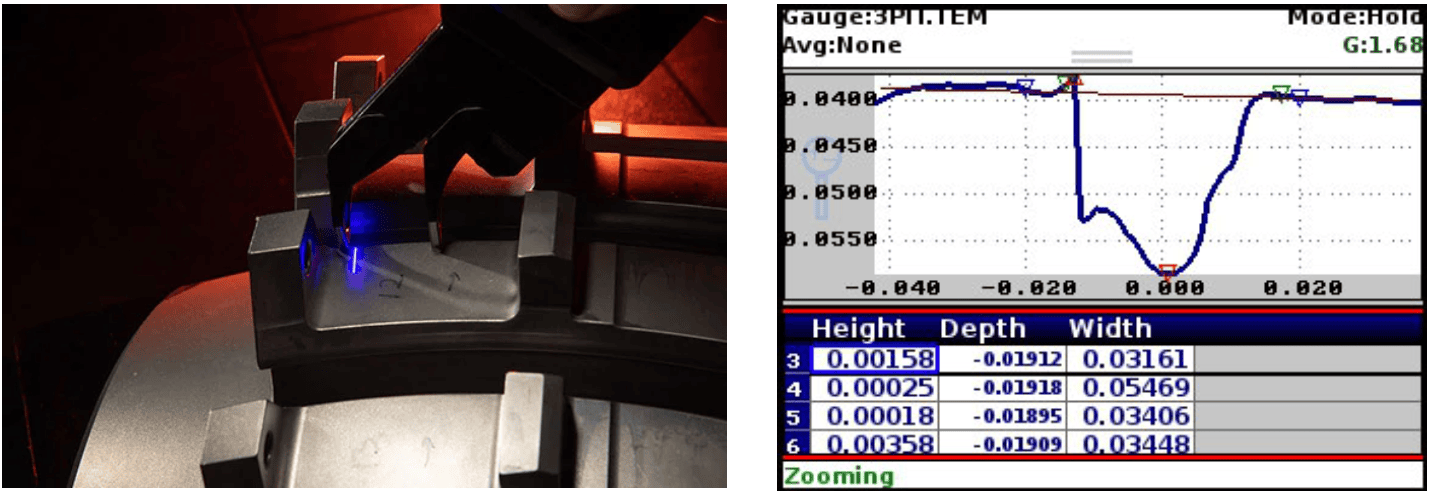

Pitting on a jet engine turbine blade requires repair once it exceeds a depth threshold. If the pitting is too severe, the blade cannot be repaired and has to be scrapped. Identifying blades that are eligible for repair saves significant costs for the airlines. Attempts have been made to visually inspect the blades and determine the depth by comparing the pitting coloration to examples or templates. Visual measurements are not always repeatable because of the different individual capabilities of the inspectors. Optical comparators have also been used, but these machines lack the portability desired.

TS800 USB SENSOR WITH BLUE LASER SINGLE STRIPE TECHNOLOGY